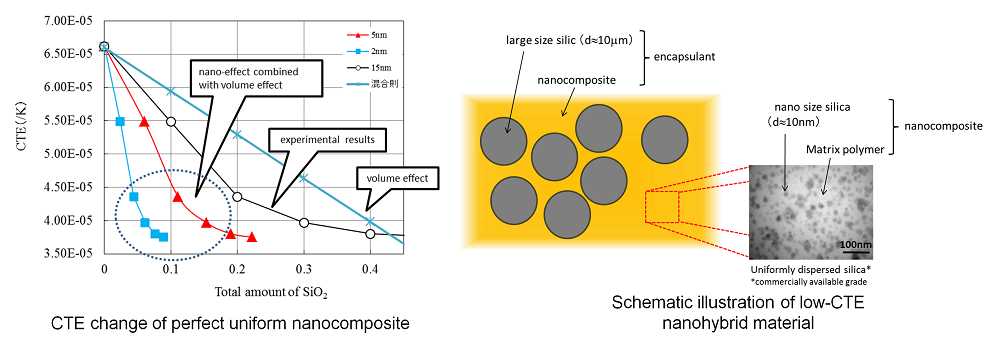

- ■Lowering the CTE more over the prediction of simple mixing rule has become to show in the nanocomposite uniformly dispersed nanoparticle of <10nm into matrix polymer.

- ■KRI will propose new R&D projects of making “perfectly uniform nanocomposite”. The key techniques are both appropriate selection of nanoparticles and their perfectly uniform dispersion into matrix.

Background & purpose of the research

- ●Nanocomposite has led to give physical property improvement due increasing interaction between nanoparticles and polymer with increasing particle specific surface area. In the many cases, however, selection of nanoparticle size and their dispersibility are ended in the insufficient levels.

- ●The ideal nanosize-effect has been thought only to complete by forming perfect uniform nanocomposite using extremely small nanoparticle under more desirable dispersion.

Characteristics of this item

1. Nanosize-effect

Nanoparticles (<10nm in diameter) have to stay in perfect uniform dispersion by adjusting interfacial affinity between particle and matrix. Under this condition, CTE of nanocomposite has been lowered remarkably by mixing slightly amount of nanoparticle.

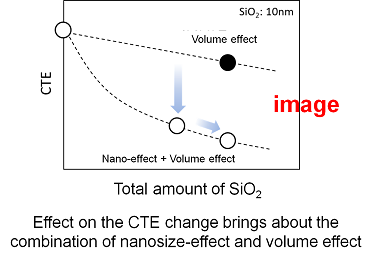

2. Combination of nanosize-effect and volume effect

The most effective way to lowering CTE is combination of nanosize-effect and volume effect. KRI focuses on this concept as a reasonable solution.

Proposal form KRI

- ●Development of Low-CTE resin

Using KRI’s organic synthesis technology and/or hybrid with the inorganic compound such as polysilsesquioxane - ●Development of encapsulant, interlayer insulation film

Target composite material using Low-CTE resin with highly dimensional stability and another inorganic filler - ●Development of functionalized adhesive

Target composition with accurately controlled CTE, with gradient characteristics