KRI selects the right electrode design for material evaluation according to the intended purpose and a standard electrode for component evaluation

Purpose / Background

Electrode fabrication technologies are vital to the performance of batteries and capacitors. The greatest amounts of time and effort are spent developing these technologies, all of which become important know-how for the company.

Failure to develop adequate technologies not only keeps excellent battery materials and components from achieving the best performance, but also risks wasting them entirely.

Information about electrode composition and properties in the evaluation report

- ●Battery material and component evaluations are greatly affected by the electrode composition (type, amount of conductive material, and amount of binders) and electrode properties (e.g., density, porosity, thickness, conductivity, and strength).

- ●KRI clearly informs clients of electrode composition and properties, thereby providing highly precise evaluation results and analysis.

- ●The electrode composition and properties are conveyed to clients as precisely as possible when the report is delivered.

Standard electrode line-up

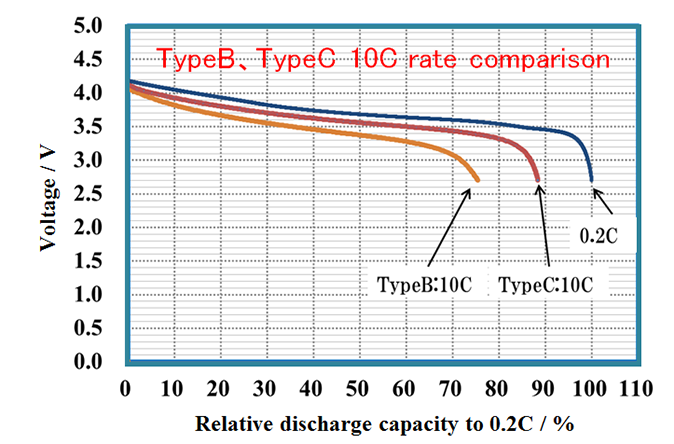

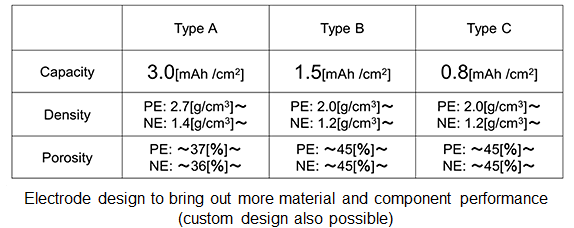

- ●Three types of standard electrodes

- ・TypeA: Evaluation for Mobile application (N-EDG01, P-EDC01, etc.)

- ・TypeB: Evaluation for PHEV application (N-ERG01, P-ERF01, etc.)

- ・TypeC: Evaluation for HEV application (N-HRG01, P-HRN01, etc.)

Electrode specification

Proposal from KRI

- ●Diversification of battery design depending on purpose and application of lithium ion battery

- ●Corresponding to required performance for each battery design is indispensable.

- ↓

- ●Standardization of evaluation electrodes (3 types)

- ↓

- Start application to the project