We offer coherent development support from materials / components development to prototyping and evaluation analysis of solid electrolyte battery.

Solid Electrolyte Research and Development Equipment

- ●Dry room for developing solid electrolyte batteries (maximum dew point -70 ℃: indoor H2S filter)

- ●Ar dry box in the dry room (dew point -80 ℃)

- ●Planetary ball mill in dry room (max, 500cc)

- ●Small electric furnace in atmosphere box

- ●Mixing machine in dry room (planetary, self-revolving type, Filmix)

- ●Electrode coating machine in dry room

- ●Roll press in dry room, 50t hot press

- ●Impedance analyzer in the dry room

- ●Large area high pressure press

- ●Simple SEM in dry room (×5000 times)

- ●Optical microscope in dry room (×5000 times)

- ●Safety test equipment (Osaka: small to large)

(H2S trap scrubber, indoor H2S filter)

Examples of KRI owned technology concerning solid electrolyte development

- ●Basic characteristics evaluation of various active materials

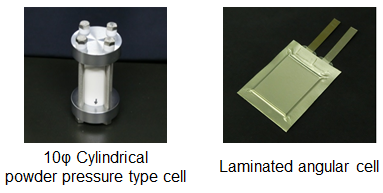

(Powder pressure type cell, Applicable to pressurization up to 1GPa) - ●Ionic conductivity / Activation energy calculation (-40℃~150℃)

- ●Basic physical properties of mixed powder in situ measurement

(0~1GPa, Compression density, electric conductivity, ionic conductivity) - ●Fabrication of sheet electrode and electrolyte sheet

- ●Laminated cell prototyping, fabrication of powder pressure type cell

- ●Evaluation of exposure for various atmospheres

- ●Evaluation of resistance to various solvents

Proposal from KRI / Future development / Expected results, etc.

- ●Application study as materials / components for solid electrolyte battery

- ●Consideration of electrode prototype process

- ●Stability study

- ●Evaluation of prototype solid electrolyte battery

- ●Evaluation analysis of solid electrolyte battery (characteristic development mechanism, deterioration mechanism, safety, etc.)