We propose next-generation material related development through development of KRI owned basic technology.

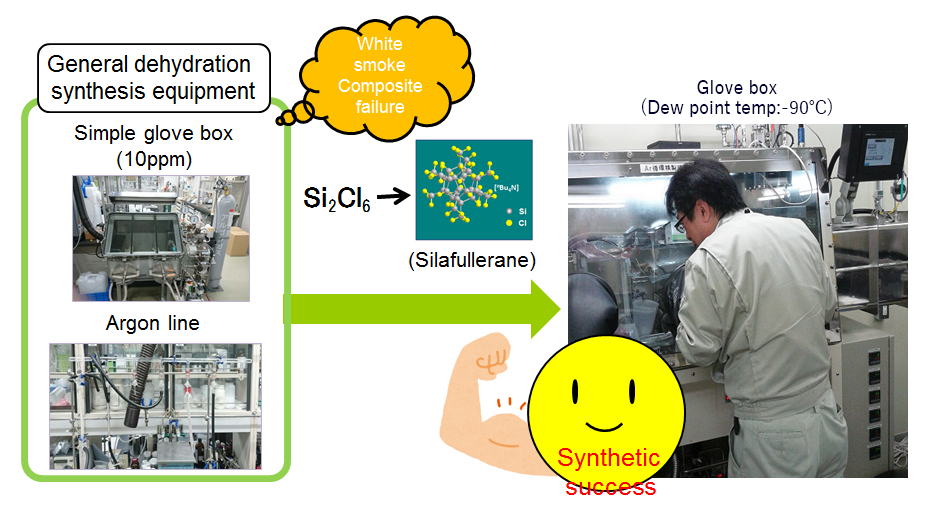

Synthetic environment provided by KRI

- ●With nonaqueous secondary battery materials such as lithium, magnesium, sodium, it could be possible to promote efficient development by eliminating the influence of water during synthesis.

- ●Isolation of unstable complexes and synthesis of synthetic intermediates can lead to elucidation of reaction mechanism.

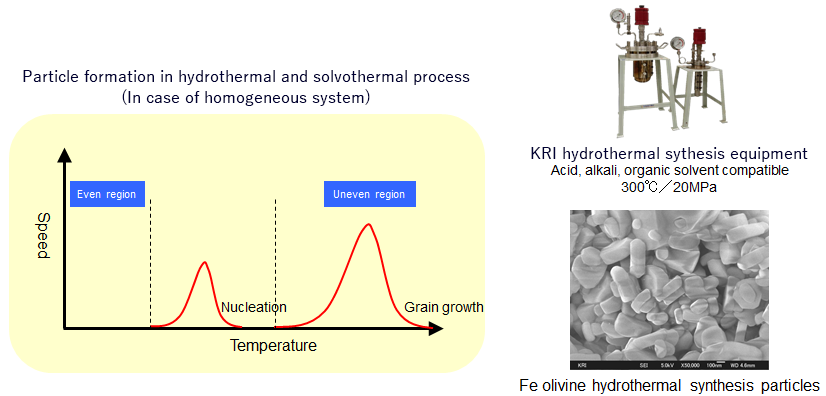

Fabrication process technology of next generation materials

After nucleation from a homogeneous system, it shifts to a heterogeneous reaction system.

Uniform particles can be obtained by appropriately selecting the transition conditions at this time.

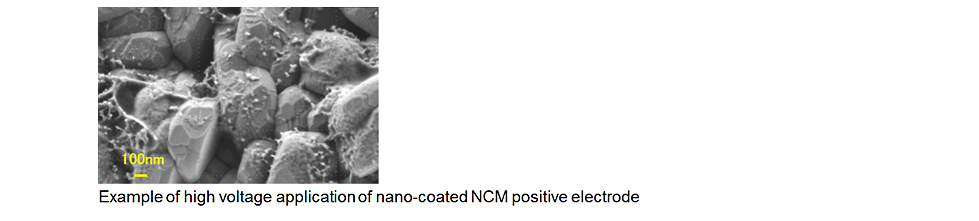

Nanocoating

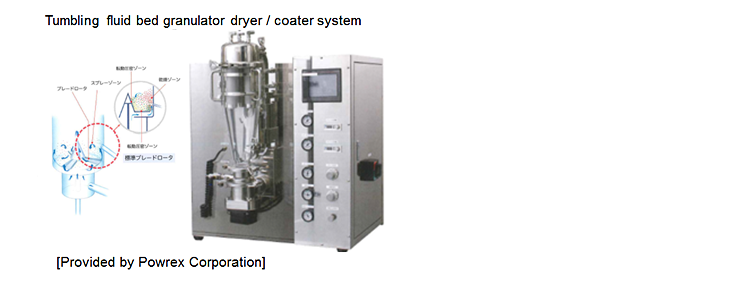

●Introduction of tumbling fluid bed granulator dryer / coater system

- ・KRI newly introduces tumbling fluid bed granulator dryer / coater system. It enables nanocoating with more precise and mass production not possible with conventional sol-gel method.

●Fusion with KRI coating technology

- ・Utilizing the knowledge of the sol-gel method, it develops into a tumbling fluid bed granulator dryer / coater system (coating material, quantity, form, etc.).

- ・Not only inorganic compounds, but also nanocoating of organic materials (polymers, etc.) are also possible.

●Expected performance by nanocoating

- ・Improvement of battery performance by nanocoating on positive and negative electrode material surface (charge / discharge cycle deterioration, input / output characteristics, gas generation, etc.)

- ・Ionic conductivity improvement and reaction suppression by nanocoating on solid electrolyte

- ・Analysis of material surface structure on battery performance

●NMR:Environment for battery related evaluation

- ・Sampling and measurement without exposing materials to atmosphere

- ・Low temperature measurement up to -100℃

- ・PFG-NMR (Molecule diffusion measurement)

[Analysis example]

- ・Solid state NMR low temperature measurement: analysis of lithium insertion state

- ・Electrolyte analysis by molecular diffusion measurement

●XRD: Structural analysis by multifunctional X-ray diffractometer

- ・Structural changes can be traced at temperature variables (−40℃~800℃)

- ・Atmosphere controllable

- ・Tracking crystal structure change in charge / discharge state

- ・Detection of trace impurities in active materials

[Analysis example]

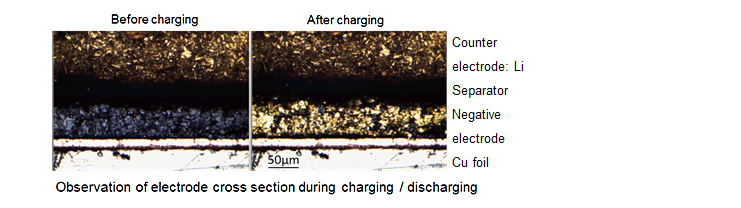

●Confocal microscope: Electrode cross section change (Operando measurement)

- ・Observation of electrode cross section during charge / discharge (particle: electrode thickness)

- ・Observation of dendrite deposition sites

- ・Observation of uneven reaction in electrodes

- ・Measurement at −30℃~80℃ is possible